|

Eddy Current Testing Process– A Definitive Guide

What does Eddy Current Inspection mean?

What does Eddy Current Inspection mean?

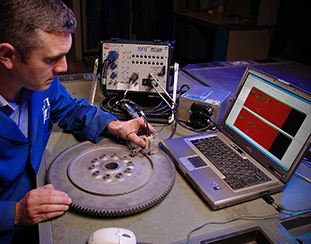

Eddy current testing (also known as eddy current inspection) is a method used in non-destructive testing, employing electromagnetism to detect surface breaking and slightly sub-surface flaws in materials. The main areas where eddy current testing (ECT) is used include crack and corrosion detection, non-conductive coating thickness measurement, material identification and heat treatment condition.

How is Eddy Current Testing Done?

Eddy current testing is carried out using a specially designed coil that is energised with an alternating current that creates a changing magnetic field surrounding the coil. The coil is placed within the proximity of a test surface where the changing magnetic field permeates the conductive material. This changing magnetic field in turn induces local electrical currents in the test surface that are known as eddy currents. These eddy currents create their own magnetic field that opposes and modifies the coil’s magnetic field, thus affecting the electrical properties of the test coil. The measurement of the changing phase and magnitude of the current flowing through the primary test coil or separate receiver-coil(s) provides the ability to determine the condition of the test sample.

Electrical conductivity and permeability variations, or the presence of discontinuities within the test-material cause a change in the eddy currents and thus a corresponding change to the phase and amplitude of the measured coil current. These changes can be displayed either individually by a needle meter or in combination on a 2D impedance plane display.

Where is Eddy Current Testing Used?

Eddy current testing is a non-destructive testing technique applicable to many industry sectors. TWI carries out non-destructive testing in a multitude of industry sectors including transport, aerospace, oil and gas, power generation and medical. ECT is therefore used in a variety of ways within these industry sectors. It can be undertaken during production, post-production, in-service and following repair.

TWI has carried out projects involving Eddy Current Testing using their expertise in non-destructive testing, these projects include:

Oil and gas sector including marine structures/applications:

- TWI carried out the inspection of external threads on a composite valve block body using an eddy current test to scan the external threads.

- TWI worked on the qualification of mechanically lined pipes. The work was carried out to address the increasing demand for conveying corrosive fluids in the sub-sea oil and gas industry. TWI tested the pipework to show that a high fatigue performance can be reached without breaching the corrosion resistant alloy’s (CRA) liner.

- The two year conversion of a shuttle tanker into a floating production, storage and offloading structure was worked on by TWI where the structure that was completed in 2017 was being inspected for critical areas using eddy current testing.

- A TWI client detected ferritic contamination in the weld pipelines of the liquefied natural gas (LNG) tank. Eddy current testing was used on the stainless steel pipework to detect the ferritic contamination.

Aerospace:

- TWI and other partners have been involved with development in non-destructive testing techniques, including eddy current testing, to enable the non-destructive techniques to easily adapt to robotic deployment.

Rail:

- TWI worked on a project that looked at advancements in rail inspection technology. Eddy current testing was an inspection technique found to be suitable for inspecting sensitive rail head surface defects.

Engineering and Fabrication:

- TWI were responsible for inspecting size serviced induced fatigue cracks for flaw detection using the non-destructive inspection technique of eddy current testing.

- TWI carried out eddy current testing to inspect the electroslag welds of a network-critical structure for a UK-based highways maintenance company prior to the 2012 Olympics.

Membership of The Welding Institute

Membership of a professional engineering institute can contribute to your career development through offering resources to further your knowledge and experience and by serving as a platform for you to showcase this knowledge and experience for others to see.

Membership of The Welding Institute offers you access to a variety of academic resources that will further your knowledge and experience. They are as follows:

- A 5% discount on TWI Training and Examination courses. Completion of these courses leads to certification.

- Members can access TWI’s Library and e-library which contain technical knowledge and information relating to Eddy Current Testing and other non-destructive testing techniques.

- You are able to attend The Welding Institute’s Technical Group Meetings and Webinars. Attendance/participation of these events allows you to gain relevant knowledge and insights into the industry sectors due to industry experts speaking and delivering presentations at these events.

- We also offer a Weldasearch service that contains over 200,000 abstracts on various engineering topics. You are able to set up monthly alerts on subjects of relevance to you.

- The Welding Institute also offers a variety of services that help you to showcase the knowledge and experience that you have gained. They include:

- The Mycareerpath tool that allows you to record your CPD information online in a simple format. This information is always available for you to access and can therefore be used to showcase your relevant experience and knowledge to potential employers or clients.

Many of our membership benefits relating to The Institute’s resources also hold the benefit of equating to CPD points. Completion of training courses, self-study using TWI’s library and e-library and attendance of Technical Group Meetings and Webinars all enable you to gain CPD points. Gaining a high number and variety of CPD points is highly respected within the engineering industry as it demonstrates that you are highly competent.

Other membership benefits, such as attendance of Technical Group meetings and other industry related events, also hold the benefit of the opportunity of networking. You are able to meet new people in the industry and create new contacts and opportunities.

An important aspect of professional registration/membership is your choice to have an identity separate from the current job role you have or the company you work for. Membership of a professional institute such as The Welding Institute will always be a respected aspect of your career that you can use to show your experience and skills to others.

The Welding Institute is able to offer you membership benefits relevant to your engineering background and knowledge. Apply to become a member and further your career opportunities!

Click here to view the Eddy Current Testing courses that TWI Training and Examination offer.